m.microtech.engineering@gmail.com View Mobile Number

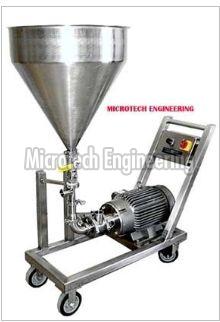

Inline Homogeniger

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of 2 Stage Inline Homogenizer, High Pressure Homogenizer, High Shear Dispersing Emulsifier, Inline High Shear Mixer and Inline Shear Pumps from delhi.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | 2 Stage Inline |

| Material | Nylon |

| Shape | Round |

| Thickness | 10-20mm, 20-30mm, 30-40mm, 40-50mm, 50-60mm, 60-70mm |

| Certification | ISI Certified |

| Application | Chemical |

| Color | Silver |

| Finishing | Polished |

| Features | Corrosion Proof, Excellent Quality, Fine Finishing |

MICROTECH ENGINEERING As one of the leading manufacturers and suppliers of industriel products, we offer best quality 2 Stage Inline Homogenizer to our clients. Our offered range helps in emulsifying, homogenizing, solubilizing, suspending, dispersing and disintegrating solids. The homogenizer, we are offering is widely popular in the market owing to its compact design, robust construction and high efficiency. This 2 Stage Inline Homogenizer is made from high grade materials and is available at industry leading prices.

Some of the other features of our product are

- Two sets of stators/rotors

- Several designs of stators are available as per the applications

- Flow rate of 850 liters per minute.

- H.S.M 410

- 10 HP Motor

- Available with gland sealing, single mechanical seal with water cooling system, single mechanical seal and double mechanical seal with thermosyphon system.

| Business Type | Manufacturer, Exporter, Supplier |

We are an acclaimed name engaged in offering our precious clients a superior quality range of High Pressure Homogenizer. Our offered homogenizer is manufactured by our professionals using high grade components and advanced technology in compliance with the industry quality standards. In addition to this, our provided homogenizer undergoes various tests under the supervision of quality controllers to ensure its flawlessness at clients' end. Clients can avail this homogenizer from us at market leading rates.

Features

- Heavy duty zinc coated frame

- Covering panel made from S. S. 304 /316 quality

- Two stage homogenization

- Low RPM plunger pump

- Pressure adjustment by hand wheel

- Sterlite coated seat ball valves for suction and discharge parts

- Spring loaded homogenizing valves

- S. S. diaphragm type sanitary design pressure gauge

- High strength steel eccentric shaft and connecting rod assembly

- Splash lubricating system

- All product contact parts of S. S. 304/316

| Business Type | Manufacturer, Exporter, Supplier |

| Type | High Shear Mixer |

| Certification | ISO 9001:2008, MS ME |

| Application | Industrial |

| Weight | 200-400kg, 400-600kg, 600-800kg, 800-1000kg |

| Color | Black, Blue, Brown, Grey, Light Green, Light White, ANY COLORS |

| Voltage | 110V, 220V, 380V, 440V |

| Condition | New |

| Automatic Grade | Automatic, Fully Automatic, Manual, Semi Automatic |

| Power | 1-3kw, 12-15kw, 15-18kw, 3-6kw, 6-9kw, 9-12kw |

| Driven Type | Electric, Hydraulic |

| Warranty | 1year |

| MOQ | AS PER CLIENT REQUIREMENT |

| Product Code | ME-HSDE |

| Port | ALL COUNTRY |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Delivery Time | READY STOCK |

| Packaging Details | WOODEN BOX. |

Working Process

MICROTECH ENGINERING High shear dispersing emulsifier effectively quickly and evenly disperse a phase or phases to another consecutive phase usually these phases are dissolvable to each other. The rotor revolves quickly and strong force is produced through high tangent speed and high frequency mechanical effect, therefore, the material in the narrow slotamong stator and rotor receives strong forces from mechanical and liquid shearing centrifugal force pressing liquid fraction clashing tearing and rush water. The dissolvable solidï¼ï¿½liquid and gas material is then instantly dispersed and emulsified evenly and finely with better production procedures and appropriate addictives and finally products with stable high quality are made.

Operation Principle

- The rotor revolves in high speed produces centrifugal force which suctions the material from upper and lower feeding area axially to the operation chamber.

- The strong centrifugal force throws the material axially to the narrow slot between stator and rotor. The material then receives centrifugal press clash and other forces which firstly disperse and emulsify the material

- The outer terminal of the rotor revolved in high speed produces a line speed more than 15ms and even up to 40m which produces strong mechanical and liquid shearing liquid abrasion clashing and tearing which fully disperse emulsify homogen and break the material and jet from the stator slot

- As materials jet in radial in high speed, they change their flow direction with resistance from themselves and vessel walls. The upperand lower axial suction force then leads to strong upper and lower rushing flows After many circulations the material is finally disper sed and emulsified evenly.

Application

- Mixing & Dissolving

- Dispraised Suspension

- mulsification

- Homogeneity

- Thick Liquid

- Chemical Reaction

- Extraction

- Depolymerization

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Shear Mixer |

| Certification | CE Certified |

| Application | Industrial |

| Weight | 200-400kg |

| Color | Silver |

| Voltage | 220V |

| Automatic Grade | Automatic |

| Power | 1-3kw, 12-15kw, 15-18kw |

| Driven Type | Electric |

| Warranty | 1year |

MICROTECH ENGINEERING In Inline agitation system, the possibility of materials –Liquid or Solid passing through it, without subjected to intense hydraulic and mechanical shear actions is zero. Here suction pipe (inlet pipe) is centrally mounted outlet is radially mounted , therefore it is physically impossible for any material to pass from inlet without exposed to agitation.

The machine is versatile has completely revolutionized the traditional mixing techniques. Here close tolerance of rotor with the stator produces high hydraulic shearing mechanical action that ensures that material entrapped between rotor stator is subjected to tremendous shearing actions each minute.

The stator which surrounds rotor is available with various type of opening i.e. round, square, rectangular with perforation also so that all the critical demand of Mixing, Emulsifying, Disintegration Dispersion of solids, suspension can be met out by same equipment.

The machine is versatile has completely revolutionized the traditional mixing techniques. Here close tolerance of rotor with the stator produces high hydraulic shearing mechanical action that ensures that material entrapped between rotor stator is subjected to tremendous shearing actions each minute.

Sealing

Single mechanical seal with Carbon, silicon carbonized phase combination is provided. Special single or double sealing is also available for conditions process which demand it eg. Latex, Abrasive solids.

Endconnection

The inlet outlet are normally fitted with . DIN, Tri Clover/ Sanitary Screw fittings but other Modes of fittings can be provided on request.

Pumpingaction

Because of indigenous design rotor operating at very high speed in close clearance with stator draws the material in imparts mechanical shearing actions. Inline Homogenizer facilitates high volume, non positive action which is sufficient to transfer the material without any supplementary pumps but in some cases because of high viscosity, vertical lift or length of pipe line , the flow rate may come down below the anticipated value, In that case it is supplemented by an auxiliary pump installed in the system which pumps the liquid without reducing the homogenizing/emulsifying efficiency of the system.

Inline Mixers

Usually called "high-shear mixers", are the most common form of Dispersing/Homogenizing/ Emulsifying mixer. By placing a form of closely-fitting shroud around a high speed impeller, it is possible to create a shearing action between the blades and stator shroud. As material is centrifugally pumped through the mixing head, some of it will see this high shear zone and experience shear stressing that results in dispersive mixing. Where small or uniform dispersions are required, material must be cycled through the head many times to ensure statistically that all of the material has passed through the high shear zone at least once.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Shear Pumps |

| Shape | Vertical |

| Use | Ground Water Supply |

| Color | Grey |

| Voltage | 220V |

| Fuel | Diesel, Electric |

| Automatic Grade | Semi Automatic |

| Power | 1-3kw, 3-5kw, 5-7kw |

| Pressure | 0-10bar, 10-20bar |

| Warranty | 1 Year |

MICROTECH ENGINEERING In Inline agitation system, the possibility of materials –Liquid or Solid passing through it, without subjected to intense hydraulic and mechanical shear actions is zero. Here suction pipe (inlet pipe) is centrally mounted outlet is radially mounted, therefore it is physically impossible for any material to pass from inlet without exposed to agitation.

The machine is versatile has completely revolutionized the traditional mixing techniques. Here close tolerance of rotor with the stator produces high hydraulic shearing mechanical action that ensures that material entrapped between rotor stator is subjected to tremendous shearing actions each minute.

The stator which surrounds rotor is available with various type of opening i.e. round, square, rectangular with perforation also so that all the critical demand of Mixing, Emulsifying, Disintegration Dispersion of solids, suspension can be met out by same equipment.

The machine is versatile has completely revolutionized the traditional mixing techniques. Here close tolerance of rotor with the stator produces high hydraulic shearing mechanical action that ensures that material entrapped between rotor stator is subjected to tremendous shearing actions each minute.

Sealing

Single mechanical seal with Carbon, silicon carbonized phase combination is provided. Special single or double sealing is also available for conditions process which demand it eg. Latex, Abrasive solids.

Endconnection

The inlet outlet are normally fitted with . DIN, Tri Clover/ Sanitary Screw fittings but other Modes of fittings can be provided on request.

Pumpingaction

Because of indigenous design rotor operating at very high speed in close clearance with stator draws the material in imparts mechanical shearing actions. Inline Homogenizer facilitates high volume, non positive action which is sufficient to transfer the material without any supplementary pumps but in some cases because of high viscosity, vertical lift or length of pipe line , the flow rate may come down below the anticipated value, In that case it is supplemented by an auxiliary pump installed in the system which pumps the liquid without reducing the homogenizing/emulsifying efficiency of the system.

Inline Mixers

Usually called "high-shear mixers", are the most common form of Dispersing/Homogenizing/ Emulsifying mixer. By placing a form of closely-fitting shroud around a high speed impeller, it is possible to create a shearing action between the blades and stator shroud. As material is centrifugally pumped through the mixing head, some of it will see this high shear zone and experience shear stressing that results in dispersive mixing. Where small or uniform dispersions are required, material must be cycled through the head many times to ensure statistically that all of the material has passed through the high shear zone at least once.

Application Of Inline Homogeniser/emulsifier Creams

- Dairy & Confectionary Items

- Beverage & Brewery

- Paper Coating

- Pharmaceuticals

- Pesticides & Insecticides

- Paints

- Natural Herbal Dye