m.microtech.engineering@gmail.com View Mobile Number

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Pumps |

| Material | Cast Iron, Stainless Steel |

| Application | All Liquied Material Lifting Up To 80 Meter, Fluids With High Viscosity |

| Click to view more | |

Product Details

The organization is a trusted name based in Delhi(India) and known for its fair pricing policy. We are backed by a team of professionals who are proficient in their respective domains and ensure that the offered lot is meticulously packed. Also, we make sure that only high quality packaging material is used for packaging.

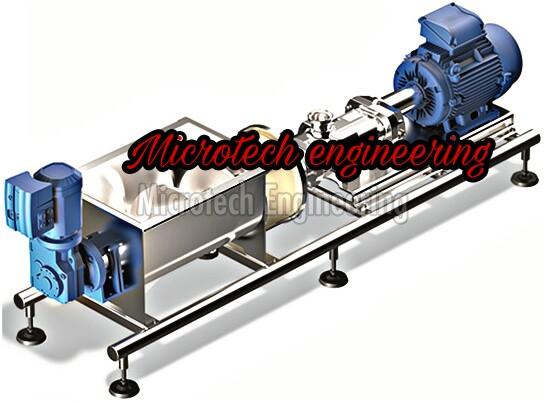

Item Code - SP : SP series Progressive Cavity Pumps find their place of applications in almost all the industries in the engineering world. Be it coal slurry or volatile chemicals, harsh abrasives or fibrous pulps, these Microtech Engineering pumps are preferred better as right choice. Whenever the pumping is found difficult, these pumps do their duty as per the user’s requirement.

Application : Acidic And Alkaline Slurry, Alum, Bentonite Slurry, Black Liquor, Casein Slurry, Ceramic Slurry, Clay Molasses, Coating Mix, Detergent Slurry, Ferrite Slurry, Fuel Oil Sludge, Glue, Grout Mix, Lube Oil, Magma, Massecuite, Molasses, Paint, Paper Pulp, Printing Ink, Rosins, Sewage Sludge, Soap Stock, Sodium Silicate, Spent Grains, Sulphited Syrup, Sugar Syrup, Cane Juice, Varnish, Vegetable Oil and Gum Sludge Viscose, Yeast, Etc.

Features

- Long life, closed or open cardan joints / pin joints.

- Reversible flow direction.

- Suction / Delivery connections in DIN / ANSI / BS

- Housing in CF8, CF8M, Alloy 20 (Fabricated AISI 304, AISI 316, AISI 316l)

- Rotor / Shaft & Rotating parts in AISI 304, AISI 316 & AISI 316L, Alloy 20, Hastealloy, optionally hard chrome plated.

- Torsion free moulded to Stainless Steel / M.S. Tube Rubber Stator in Natural, Nitrile, EPDM, Hycar, Butyle, FPM, Silicon, Hypalon.

- Shaft Sealing by Stuffing Box Gland Packed / Mechanical Seal