m.microtech.engineering@gmail.com View Mobile Number

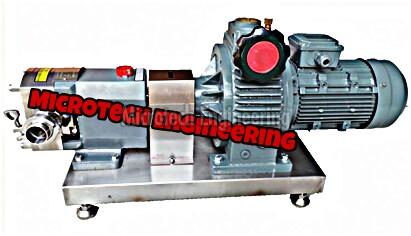

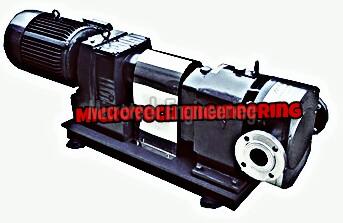

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Transfer Pump |

| Certification | CE Certified |

| Weight | 100-300kg |

| Click to view more | |

Product Details

Microtech engineering Lobe pumps are used in a variety of industries including, pulp and paper, chemical, food, beverage, Pharmaceutical, and biotechnology. They are popular in these Diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics. These pumps offer a variety of lobe options including single, biwing, tri-lobe (shown), and multi-lobe.Rotary lobe pumps are Non-contacting and have large pumping chambers, allowing them to handle solids such as cherries or olives without damage. They are also used to handle slurries, pastes, and a wide variety of other liquids. If wetted, they offer self- priming performance. A gentle pumping action minimizes product degradation. They also offer reversible flows and can operate dry for long periods of time. Flow is relatively independent of changes in process pressure, so output is constant and continuous.

How Lobe Pumps Work Liquid flows into the cavity and is trapped by the lobes as they rotate :

- Lobe pumps are similar to external gear pumps in operation in that fluid flows around the interior of the casing. Unlike external gear pumps, however, the lobes do not make contact. Lobe contact is prevented by external timing gears located in the gearbox. Pump shaft support bearings are located in the gearbox, and since the bearings are out of the pumped liquid, pressure is limited by bearing location and shaft deflection.

- As the lobes come out of mesh, they create expanding volume on the inlet side of the pump

- Liquid travels around the interior of the casing in the pockets between the lobes and the casing it does not pass between the lobes.

- Finally, the meshing of the lobes forces liquid through the outlet port under pressure.

- Lobe pumps are frequently used in food applications because they handle solids without damaging the product. Particle size pumped can be much larger in lobe pumps than in other Positive Displacement Pump types. Since the lobes do not make contact, and clearances are not as close as in other Positive Displacement Pump, this design handles low viscosity liquids with diminished performance. Loading characteristics are not as good as other designs, and suction ability is low. High-viscosity liquids require reduced speeds to achieve satisfactory performance. Reductions of 25% of rated speed and lower are common with high-viscosity liquids.

Advantages

- Pass medium solids

- No metal-to-metal contact

- Superior CIP/SIP capabilities

- Long term dry run (with lubrication to seals)

- Non-pulsating discharge

Disadvantages

- Requires timing gears

- Requires two seals

- Reduced lift with thin

Application : Alcohol - Apple pure – Apricots - Baby food – Batter – Beans – Beer Beetroot - Biscuit Cream – Blackcurrants – Brine –Broth -Butter fat Caramel - Castor Oil - Cat food - Cheese curd - Cheese whey – Cherries - Chicken paste - Chili con – Carne –Chocolate – Chutney – Cockles - Coconut oil - Cod oil – Coffee –liquor – Cordials -Corn oil - Corn syrup – Cottage – cheese - Cotton seed – oil –Cranberry --- juice - Cream – Cream cheese – Custard - Dog food – Dough – Eggs – whole - Egg yolk – Essences – Evaporated –milk -Fish –- Iodine - ointment etc.